Background

With the trend of oil feld digitization gaining momentum, telematics can be tremendously useful in understanding equipment status so as to facilitate predictive maintenance and to avoid operation downtime. Leading oil and gas service companies are building telematics solutions for their customers to run smooth operations and conduct predictive maintenance for artifcial lifts in oil felds. Collecting the data generated by the equipment during operations is the key to achieving this goal.

Case

One of Elastel customers that oil and gas service companies need a reliable and secure solution to ensure that the data is brought back to the control center for further analysis

System Requirements

- Computer systems that are small enough to ft inside existing control cabinets, and have low power consumption and hazardous location stability

- Reliable 4G LTE connectivity in high operating temperatures for constant data aggregation

- Supports PLC protocols for data acquisition and update

- Open platform for custom application development

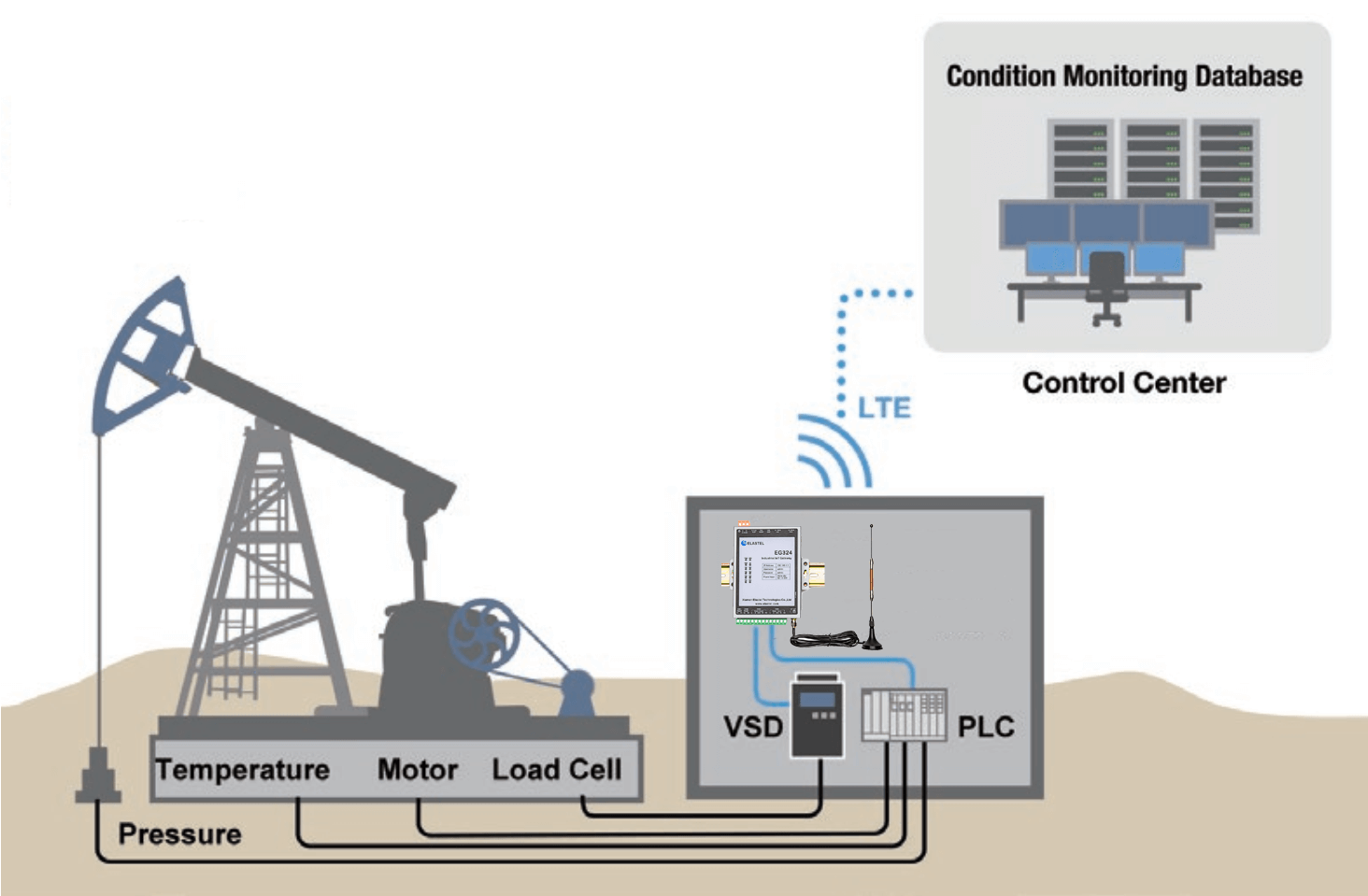

System Architecture

Why Elastel

- Compact Arm-based EG324 IIoT gateway compliant with industrial standards for harsh environments

- Reliable LTE connectivity in a wide operating temperature range of -40 to 85°C

- Web-based local SCADA software easy-to-configure and maintain slave devices

- Ubuntu open platform for rapid development of customer applications for variable speed drives (VSDs) and PLCs

Featured Product

EG324 IIoT Gateway

Arm-Based IoT Gateway provide a high-performance computing platform for embedded data acquisition and communication applications.

- Armv7 Quad-core Cortex-A9 1.4 GHz CPU, 512MB RAM + 8GB eMMC

- 4x Isolated RS485/RS232 for industrial data acquisition

- Dual auto-sensing 10/100 Mbps Ethernet

- Mini-PCIe slot for 4G LTE/3G/2G/NB-IoT/Cat M1 Cellular Network

- -40°C to +85°C Operating Temperature.