5 Applications of industrial Raspberry Pi usages as a soft PLC

April 20, 2022EG500 CE/FCC/ROHS/RCM Certificates Approved

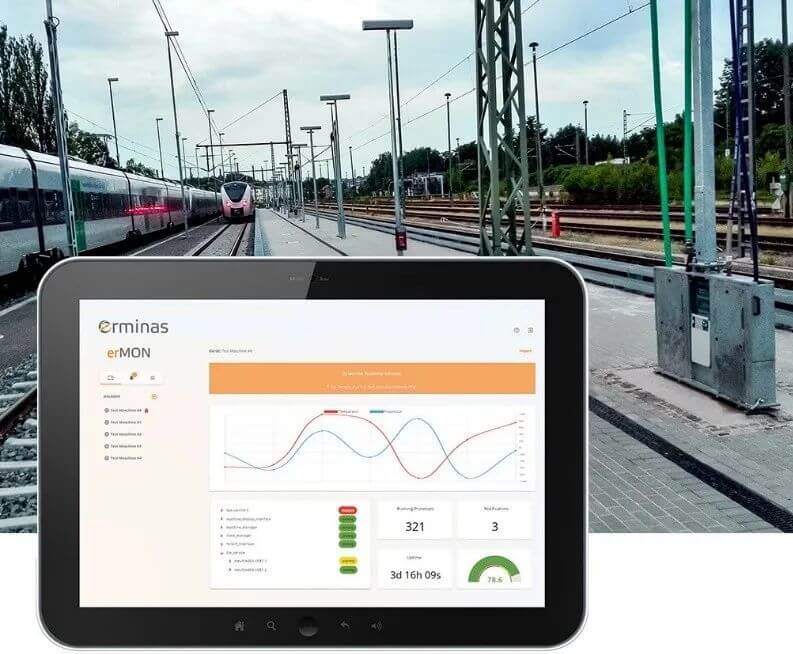

December 20, 2022The purpose of IIOT (Industrial Internet of Things), simply to say is to collect data from various devices for monitoring and control, and to share the data with other systems, so that to realize the Internet of things.

In this process, there are three major parts need to be considered.

The first is the docking of equipment in the industrial field, the so-called OT network. In the traditional OT network, PLC acts as a logical controller to monitor and control the status of executing equipments on site to ensure the coordinated and orderly operation, various sensors collect data and feedback, and HMI/SCADA system monitors the running status of the whole factory.

Since each automation equipment manufacturer carries out different communication protocol standards, the industrial communication network composed by core PLC may also adopt different communication protocols. The complexity of communication protocols is the first important challenge for the Industrial Internet of Things.

The second part is data sharing, that is connecting to IT network. IT engineers are likely to be more familiar with technologies such as databases, high-level language programming, network communications... This is quite different from the technology involved in OT networks.

On the premise that the Industrial Internet of Things can be compatible with OT network, can also use various IT technologies for data docking. Therefore, for the Industrial Internet of Things, in order to achieve better interconnection, the integration of IT and OT is a process that must be experienced.

The third part is edge data computing. The raw data from the fields is often not the data we really want.

What we really need is to explore the value behind the data, which involves the necessary processing of the original data. Of course, we can send the raw data directly to the cloud/server for data processing, but this often leads to efficiency issues and network bandwidth pressures. A better approach would be to process the raw data collected directly at the edge.

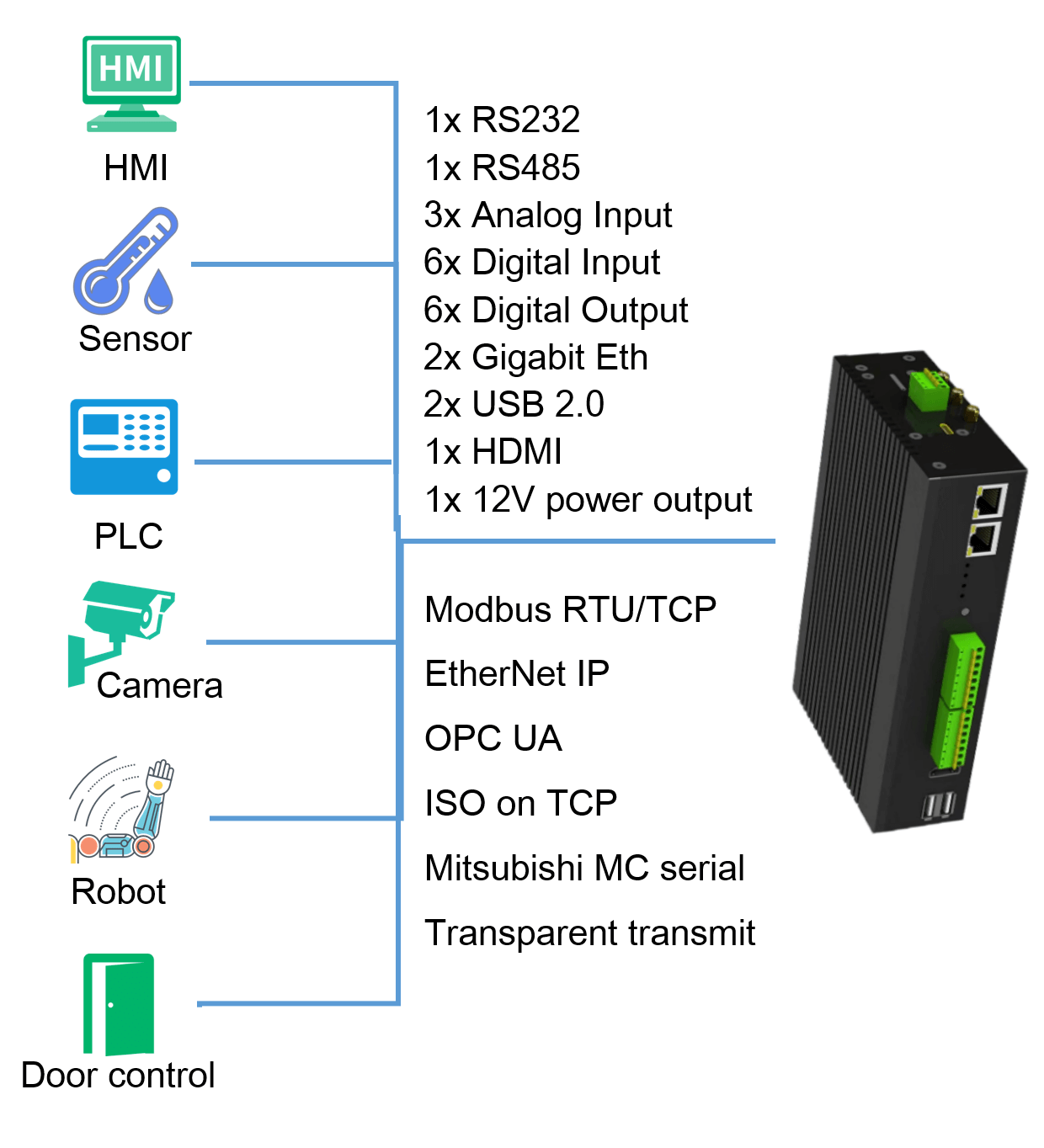

Dual GbE, 1xRS485, 1x RS232, 6x DI, 6x DO, 3xADC, EG500

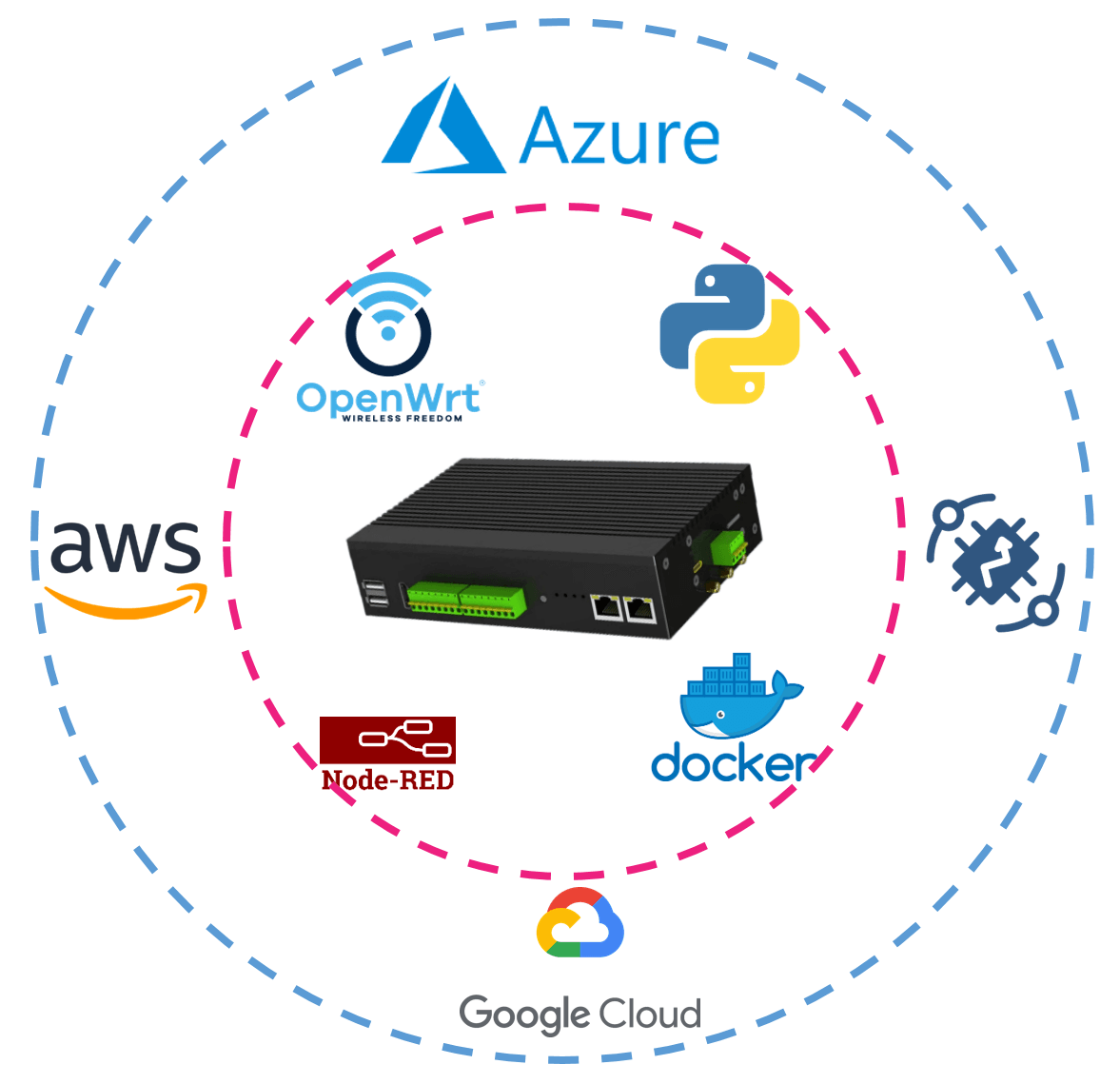

The ELASTEL Industrial Raspberry Pi Gateways combined with CODESYS can solve the 3 major challenges mentioned above.

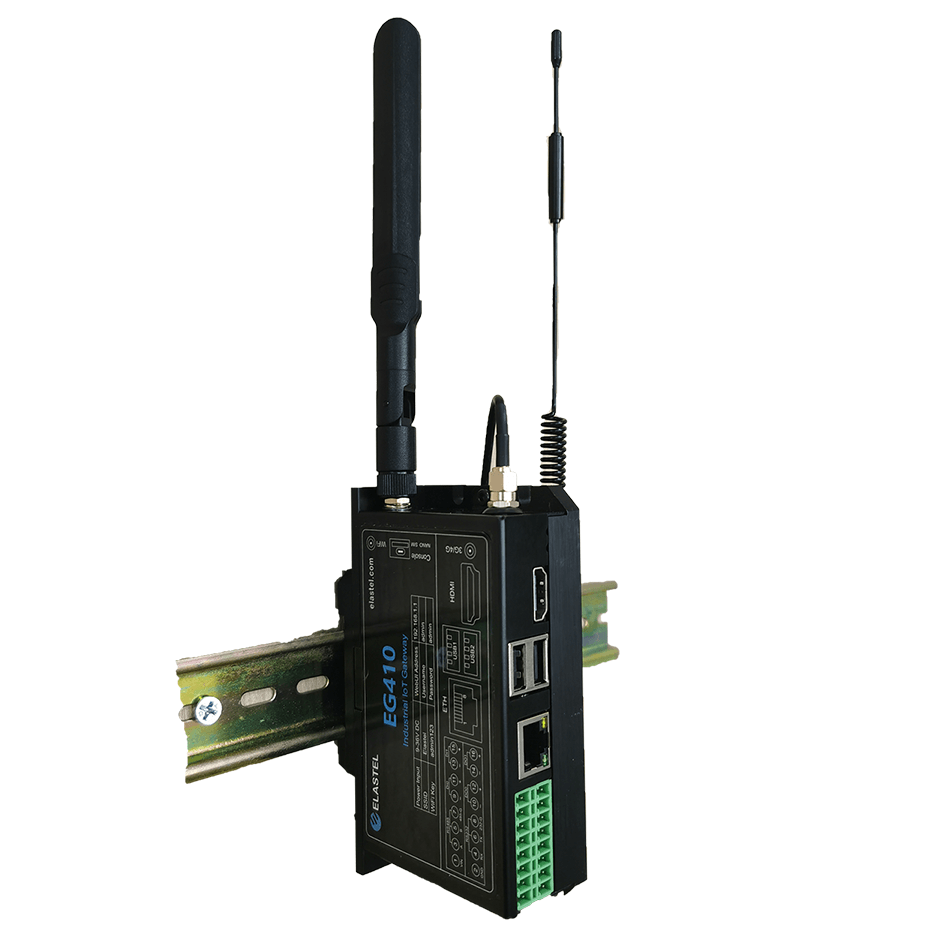

The Elastel EG410 and EG500 IoT Gateways powered by Raspberry Pi, which give. them unique advantages in the implementation of IT technology.

First of all, EG410 and EG500 inherit the advantages from Raspbian OS, which means over 35,000 software packages or pre-compiled software comes from Raspbian can be used directly on Elastel IoT Gateways, and users can configure and secondary develop on it with a high degree of freedom.

In addition, raspberry PI's active community support is also a great engine to Elastel IoT Gateway. From basic high-level programming language support (such as Python, Java, C, C++, etc.), to pre-installed Node-Red environments, enhanced the Elastel IoT Gateways a wide range of possibilities.

Elastel IoT Gateway is designed for industrial applications. To adapt to harsh industrial environments and stringent requirements, the following changes are made:

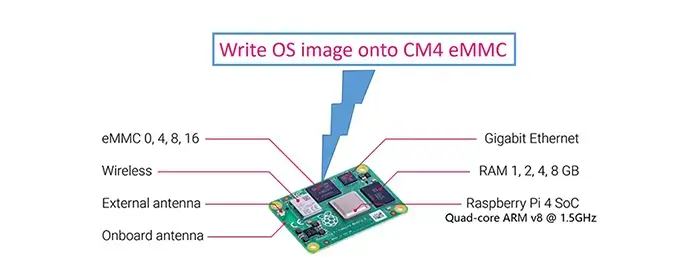

- Based on the raspberry PI computing module CM4, industrial packaging and testing.

- Add real time (RT) patches to Raspbian

- Discard unstable GPIO interfaces and develop isolated RS485/232/DIO/AIO terminal ports.

- Fanless cooling technology to suit a wide temperature range from -25~70℃

- Fieldbus support (Modbus master/slave, EtherCAT, PROFINET, CANopen and other common protocols)

However, it would have been more difficult to develop just using RevPi itself, which might have required users to build applications from scratch, fortunately the CODESYS solved this problem.

CODESYS software itself is to support a variety of industrial Ethernet/fieldbus protocol master station implementation, in the CODESYS programming environment without complex protocol communication program development, just a simple configuration in CODESYS IDE. Elastel IoT Gateway take the advantages from CODESYS following examples:

- Support for all languages under IEC 61131-3 standard (SFC, LD, FDB, ST, IL, CFC), which is more friendly to OT engineers

- Visual interface development platform for remote monitoring

- Industrial grade real-time operating system kernel to convert any device ported to CODESYS Runtime to industrial controls conforming to IEC 61131-3

- Motion control library, which is also a major advantage of CODESYS

- Field bus protocol stack, CODESYS provides a variety of field bus support, such as Profibus, Profinet, EtherCAT, CANopen, Modbus, etc

- OPC UA support .......

-

Obviously, CODESYS perfect functions not only make up the weakness of Elastel IoT Gateways for OT networks, but also further support EG410 and EG500 with powerful control functions. All of these make EG410 and EG500 perfect as IIoT edge smart gateway.

* Using CODESYS on EG410 and EG500 may requires the additional licenses purchase.

For More details about CODESYS on Elastel products, please contact our representative.